4 Easy Facts About Roar Solutions Shown

4 Easy Facts About Roar Solutions Shown

Blog Article

The Best Guide To Roar Solutions

Table of ContentsWhat Does Roar Solutions Do?Some Known Details About Roar Solutions Rumored Buzz on Roar Solutions

In order to safeguard setups from a potential explosion a technique of analysing and classifying a possibly harmful area is required. The objective of this is to guarantee the correct selection and installation of tools to ultimately protect against a surge and to guarantee safety of life.

(https://www.cheaperseeker.com/u/roarsolutions)

No tools ought to be mounted where the surface temperature of the devices is more than the ignition temperature level of the offered hazard. Below are some common dust dangerous and their minimum ignition temperature level. Coal Dirt 380C 225C Polythene 420C (thaws) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dirt 510C 300C Phenolic Material 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Residue 810C 570C The probability of the threat being present in a concentration high adequate to trigger an ignition will vary from area to place.

In order to identify this threat an installation is divided right into locations of risk relying on the quantity of time the harmful exists. These locations are referred to as Zones. For gases and vapours and dirts and fibres there are three zones. Area 0 Zone 20 An unsafe environment is very likely to be present and may be present for extended periods of time (> 1000 hours annually) or even continually Zone 1 Zone 21 A harmful environment is feasible but unlikely to be existing for extended periods of time (> 10 450 C [842 F] A classification of T6 means the minimal ignition temperature level is > 85 C [185 F] Unsafe location electrical devices maybe designed for use in greater ambient temperatures. This would certainly suggested on the rating plate e.g. EExe II C T3 Ta + 60C( This suggests at 60C ambient T3 will not be gone beyond) T1 T1, T2, T3, T4, T5, T6 T2 T2, T3, T4, T5, T6 T3 T3, T4, T5, T6 T4 T4, T5, T6 T5 T5, T6 T6 T6 A T Class rating of T1 implies the maximum surface area temperature produced by the instrument at 40 C is 450 C. Thinking the associated T Course and Temperature level score for the devices are proper for the area, you can constantly utilize an instrument with an extra strict Department rating than required for the location. There isn't a clear answer to this inquiry. It really does rely on the sort of devices and what repairs require to be accomplished. Tools with particular test procedures that can not be performed in the field in order to achieve/maintain 3rd celebration score. Should return to the factory if it is before the equipment's service. Area Fixing By Authorised Worker: Difficult testing may not be needed nonetheless specific procedures might require to be followed in order for the devices to maintain its third event score. Authorized employees have to be utilized to execute the job appropriately Repair work need to be a like for like substitute. New part must be thought about as a straight substitute calling for no unique screening of the equipment after the repair work is total. Each tool with a harmful ranking ought to be assessed separately. These are outlined at a high level below, but for more comprehensive info, please refer directly to the guidelines.

The 7-Minute Rule for Roar Solutions

The equipment register is a detailed database of equipment records that includes a minimum collection of fields more helpful hints to determine each product's place, technical parameters, Ex category, age, and environmental data. The ratio of Comprehensive to Shut evaluations will be established by the Tools Risk, which is assessed based on ignition threat (the likelihood of a source of ignition versus the probability of a combustible environment )and the harmful area category

( Zone 0, 1, or 2). Carrying out a robust Risk-Based Evaluation( RBI )strategy is critical for making sure compliance and safety and security in taking care of Electrical Equipment in Hazardous Areas( EEHA).

Some Known Questions About Roar Solutions.

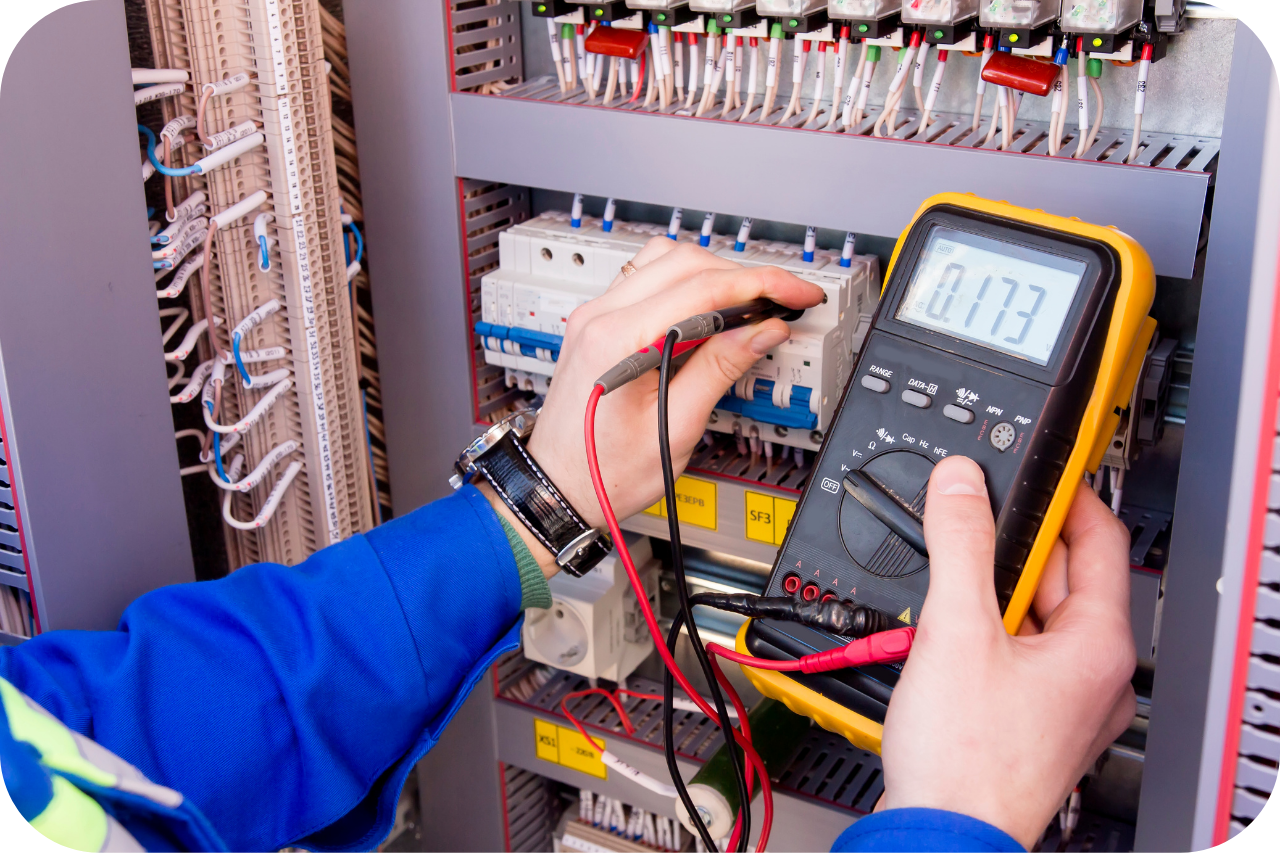

In regards to explosive threat, an unsafe area is an environment in which an eruptive environment exists (or might be anticipated to be present) in quantities that require special preventative measures for the building, setup and use devices. hazardous area electrical course. In this short article we discover the difficulties faced in the workplace, the threat control measures, and the called for expertises to function securely

It is a repercussion of modern-day life that we produce, keep or deal with a series of gases or liquids that are regarded flammable, and a variety of dirts that are considered flammable. These compounds can, in specific problems, form eruptive ambiences and these can have major and tragic repercussions. A lot of us are familiar with the fire triangular get rid of any kind of one of the 3 elements and the fire can not take place, but what does this mean in the context of harmful locations? When damaging this down into its easiest terms it is basically: a mix of a specific quantity of launch or leakage of a specific material or product, combining with ambient oxygen, and the presence of a source of ignition.

In the majority of instances, we can do little concerning the degrees of oxygen airborne, but we can have significant impact on resources of ignition, as an example electric tools. Hazardous locations are recorded on the hazardous location category drawing and are recognized on-site by the triangular "EX-SPOUSE" indicator. Here, among other key details, zones are split right into 3 kinds relying on the danger, the probability and period that an eruptive environment will exist; Zone 0 or 20 is deemed the most unsafe and Zone 2 or 22 is deemed the least.

Report this page